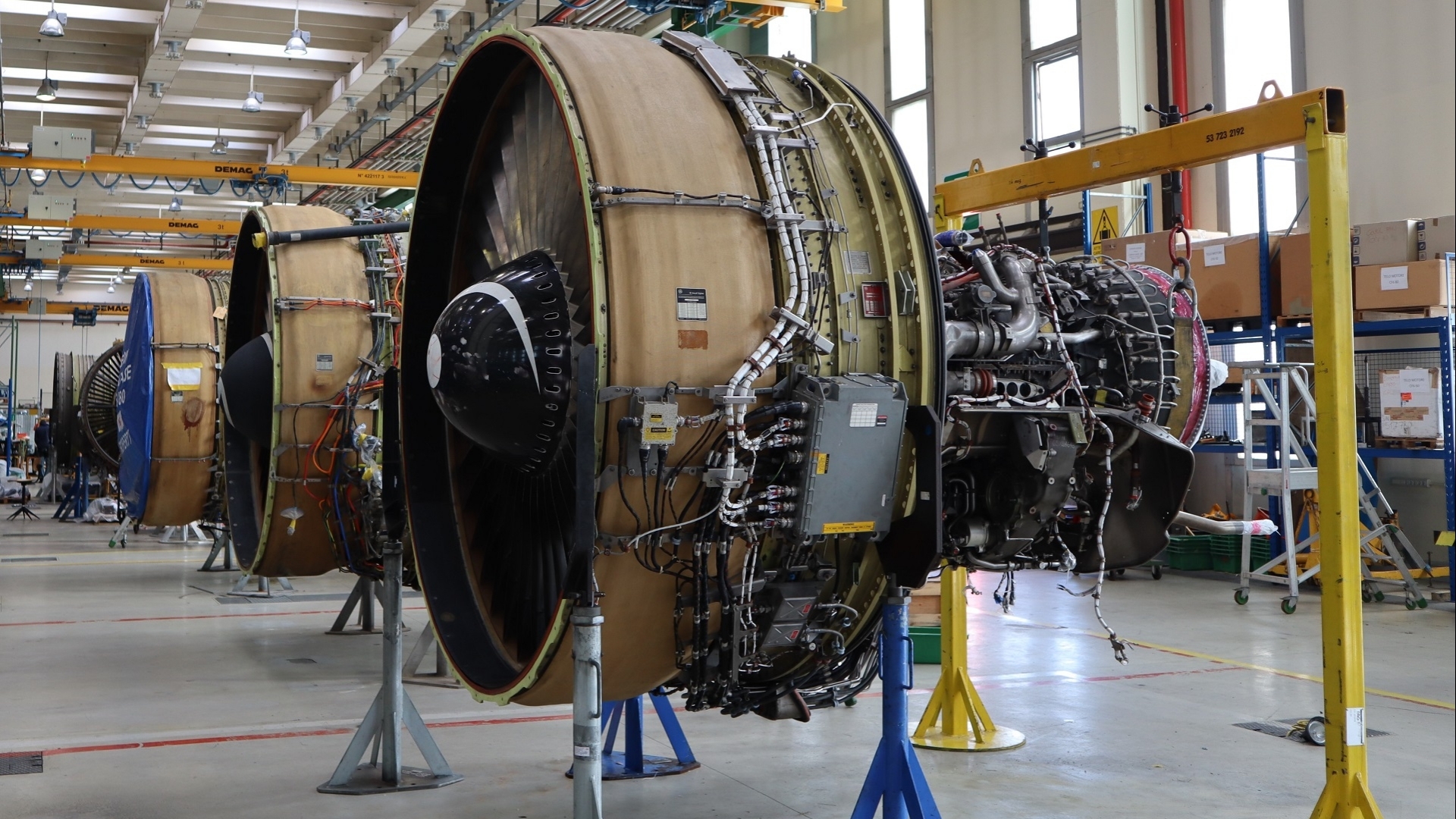

The IAG Engine Centers are a world-class engine service provider. Each have industry-leading MRO capabilities and extensive experience to provide customized solutions across an array of aircraft engines. The company services CFM56, CF6, PW4000, and JT9D model engines from around the world supported by its USA and Europe locations.

The modern aircraft engine is an intricate and multiplex system. The IAG Engine Centers have one of the most comprehensive engine portfolios on the market. The company supports a wide selection of engine types and is continually developing its line of services. It offers a complete range of MRO solutions for commercial aircraft engines. A variety of new advancements in the field of maintenance and repair technologies allow the company to be optimally supported between scheduled shop visits. The professionals at the IAG Engine Centers consist of OEM and U.S. military trained technicians with extensive experience in major airlines, MRO, and governmental agencies.

The IAG Engine Centers are committed to lowering its customers' per cycle engine maintenance costs, while maximizing their length of time on-wing. The company takes pride in its exceptional reputation with its MRO customers. The company customizes each shop visit to provide the best and most comprehensive support, while optimizing the total package to meet customers' operational and financial targets. The work-scopes are tailored to the engine condition and the engine shop visit objective. At the end, the IAG Engine Centers return the aircraft engine to revenue service faster while reducing overall cost of ownership.

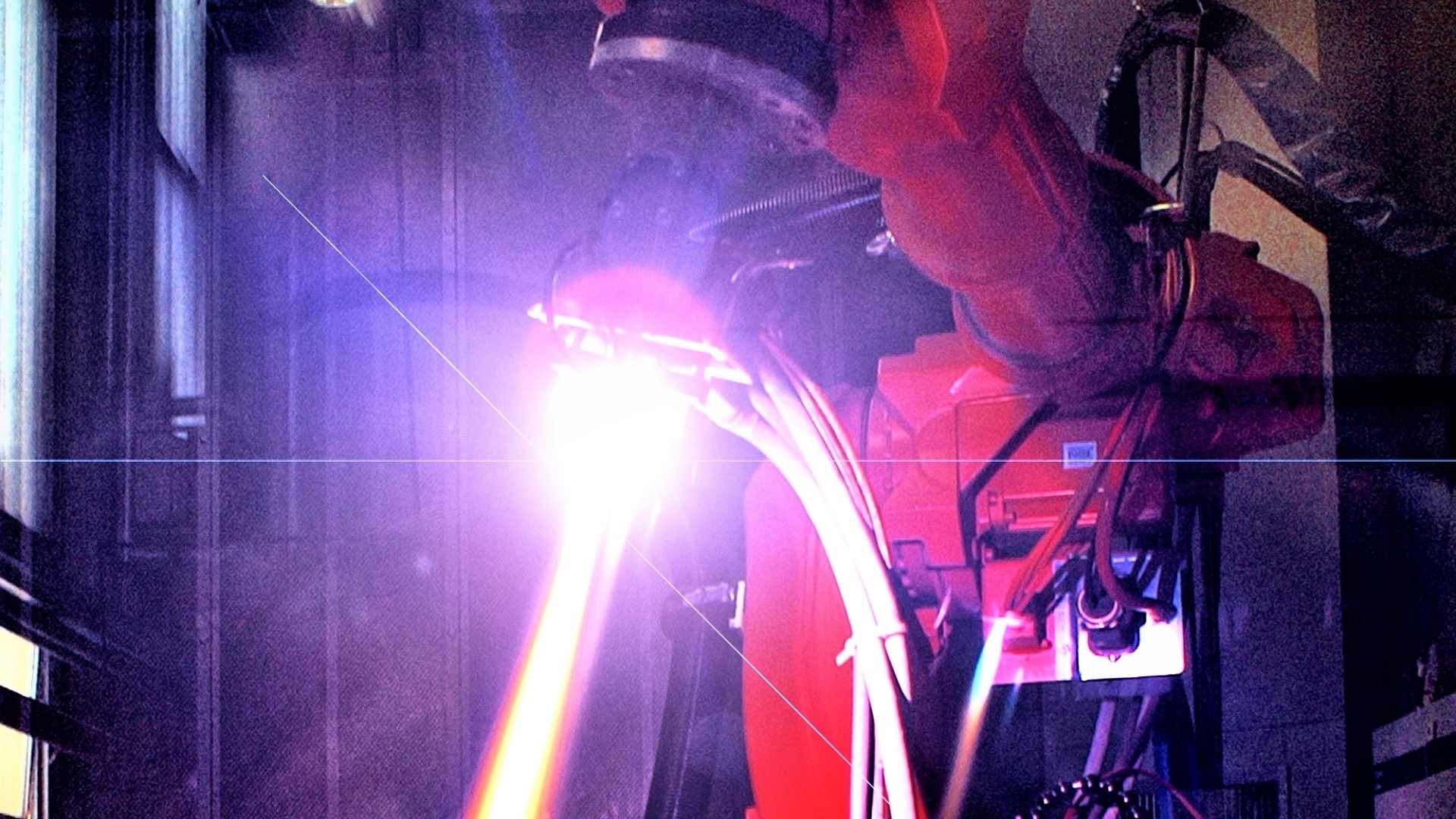

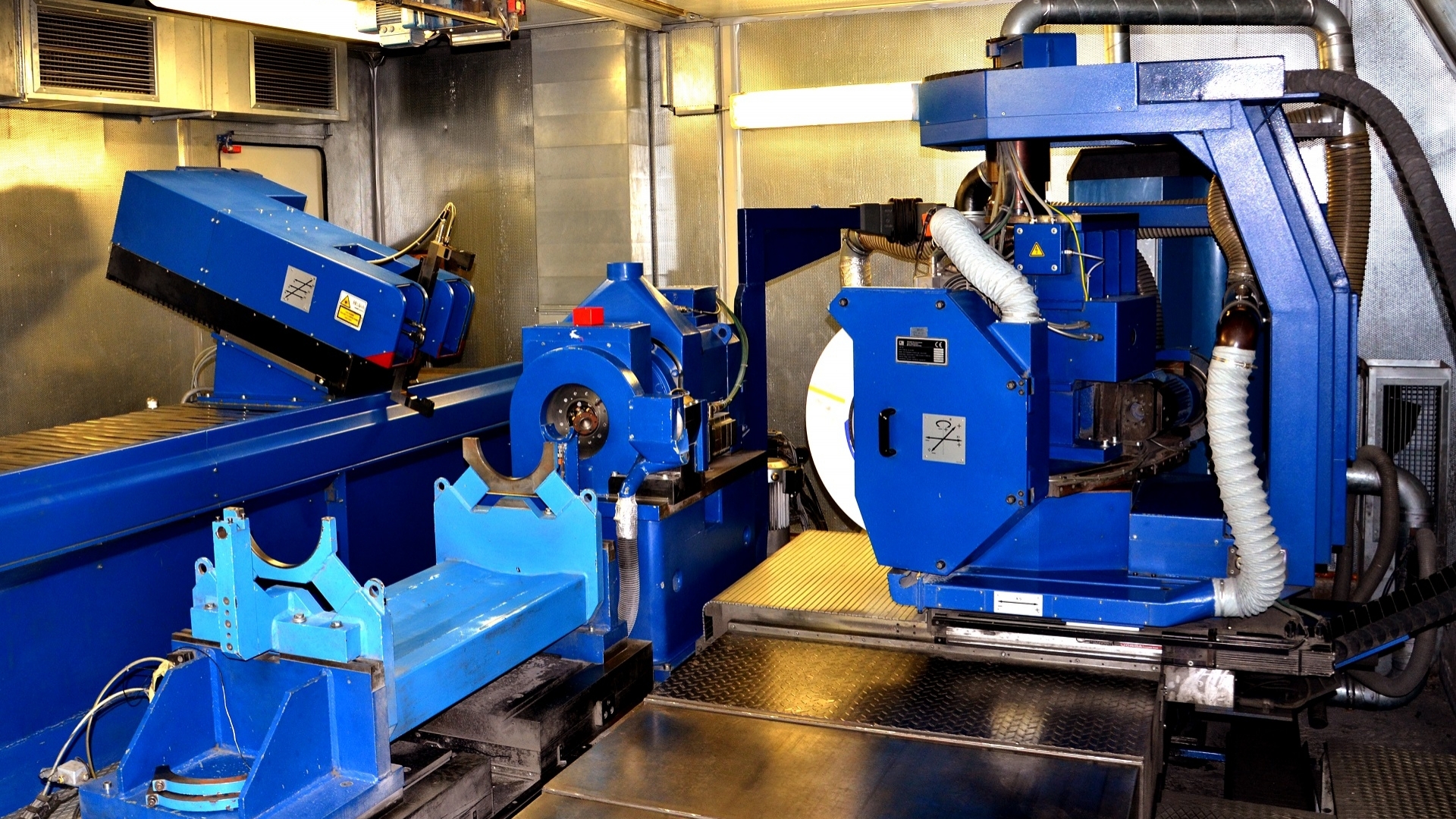

The IAG Engine Centers' innovative technology enhances performance and reduces operational costs. The company uses a two-fold maintenance approach combined with evaluation and cost-benefit analysis tools to meet customers' needs. The tools use reliability-centered maintenance (RCM) fundamentals and cost models to provide customers with potential work-scopes for their engines. With the use of maintenance history, statistical reliability prediction data, and known failure rates help determine a specialized maintenance strategy for future engine repair and overhauls. The IAG Engine Centers' technologies reduce the cost of ownership of the engines and the aircraft they power.

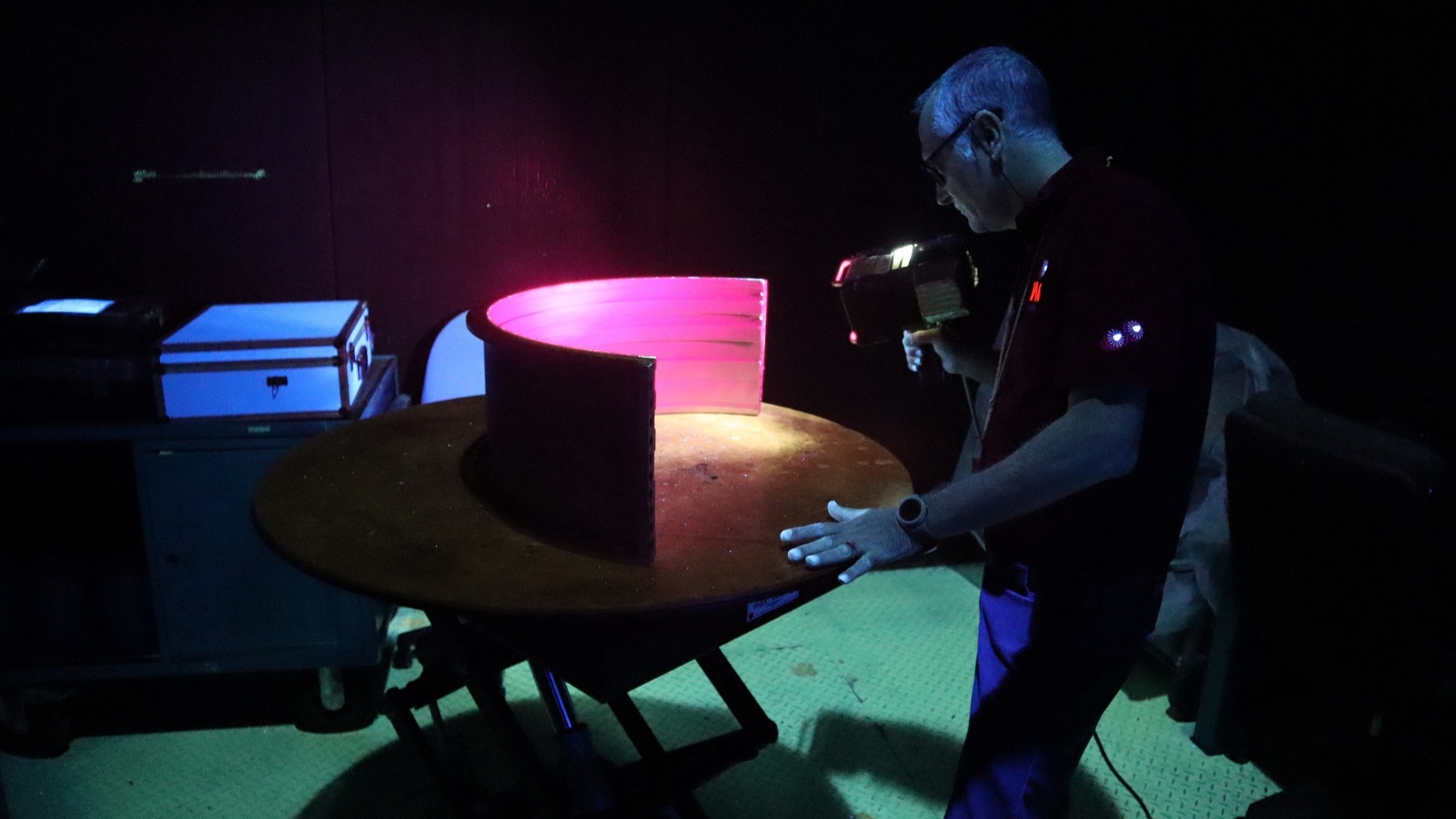

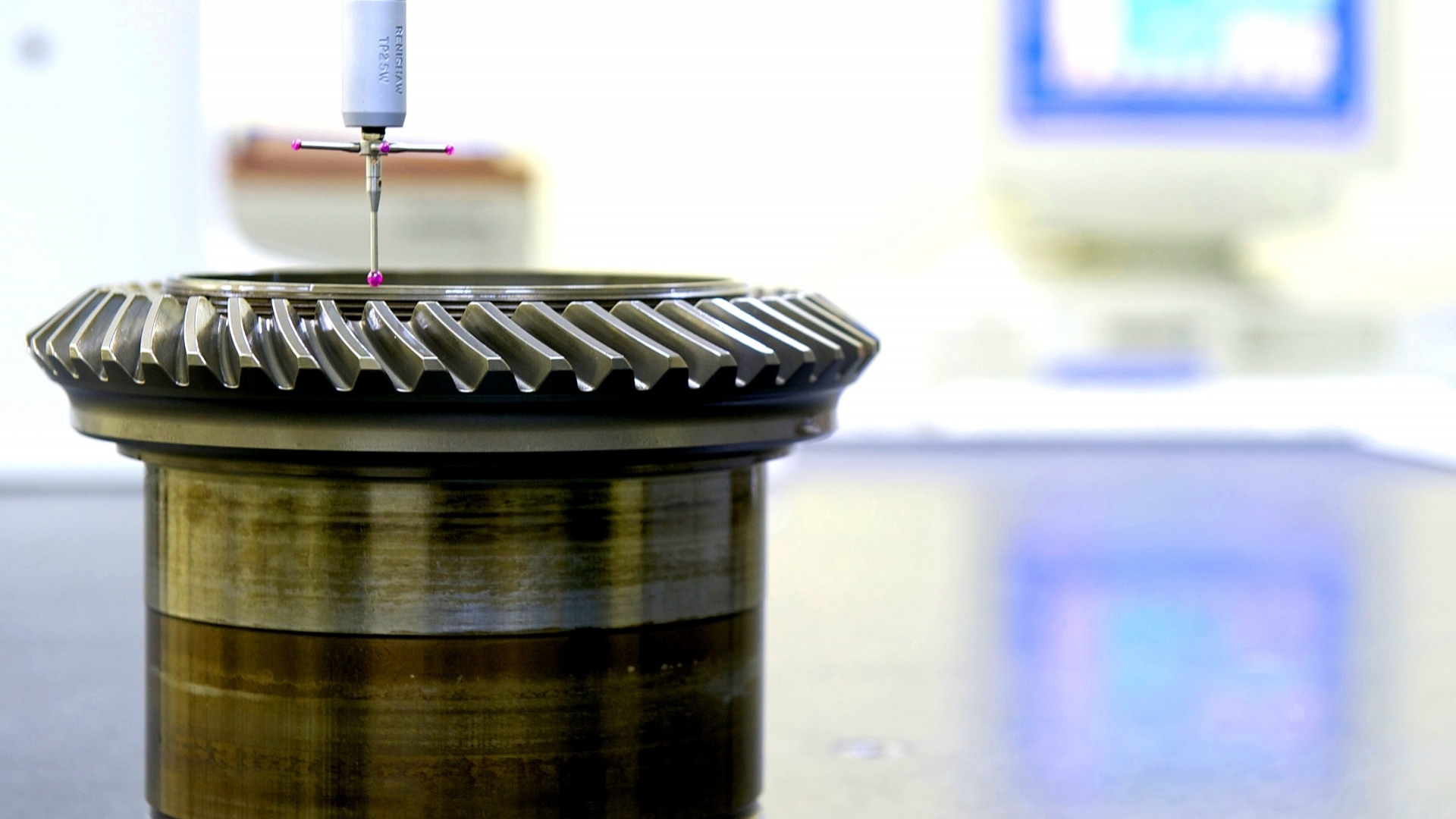

Advanced technologies include: