The barriers to entry in the additive manufacturing industry can be challenging to say the least. We are here to be your go-to resource for anything additive—giving you the resources you need to develop a final product that can be produced on a commercial scale.

We offer closed loop solutions from prototyping to production. Our services include material development, feedstock creation, printer selection

and tuning, part design, printing, and characterization.

Custom Material Development for AM

Create your custom material for pellet, filament, polymeric micropowder, and UV resin applications.

Part Design and Printing Services

Take advantage of our short-run manufacturing or our service bureau services.

Printer Tuning for 3rd Party Materials

Calibrate additive manufacturing platforms for your specific material needs.

Customer Education/Seminars

Learn from our experts on relevant AM topics and join seminars hosted at the Cervenka Center.

Development Projects for Target AM Applications

Develop materials and solutions for your AM applications—from prototyping to production.

Material/Process Consulting Services

Speak with our in-house experts to enable technology adoption and to discuss AM challenges.

WHY CHOOSE EMPOWR3D™?

You won’t be limited to a predetermined printer or software set-up either—our goal is to be an open-source hub of additive manufacturing development. Join EMPOWR3D™ to open new additive manufacturing possibilities.

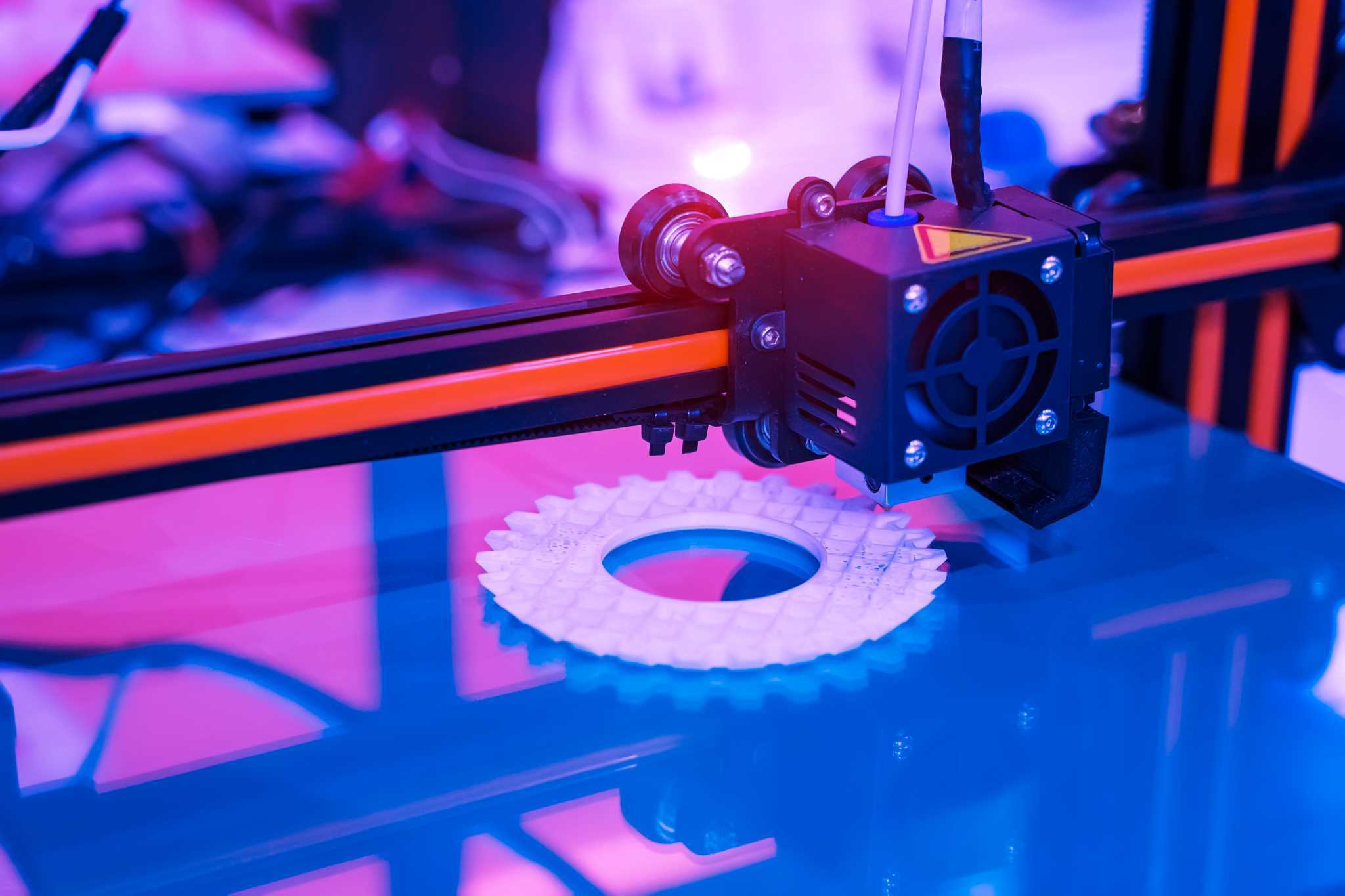

PRINTER CAPABILITIES

- Vat polymerization

- Thermoplastic extrusion

- Powder bed fusion

- Binder jetting

MATERIALS DEVELOPMENT AND FORMULATION WORK

- Stereolithography (SLA)/Digital Light Processing (DLP)/Continuous Liquid Interface Production (CLIP)

- Fused deposition modeling (FDM)/fused filament fabrication (FFF)/pellet

- Selective laser sintering (SLS)

MATERIALS CHARACTERIZATION AND ANALYSIS

- Chemical characterization (Fourier Transform Infrared Spectroscopy (FTIR), gel permeation chromatography (GPC), highperformance liquid chromatography (HPLC)

- Materials characterization (Dynamic Mechanical Analysis (DMA), differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), flexural, tensile, impact, color, heat deflection temperature (HDT)

- Morphology characterization (scanning electron microscopy (SEM), particle size analysis)

OUR PREMIER PARTNERS